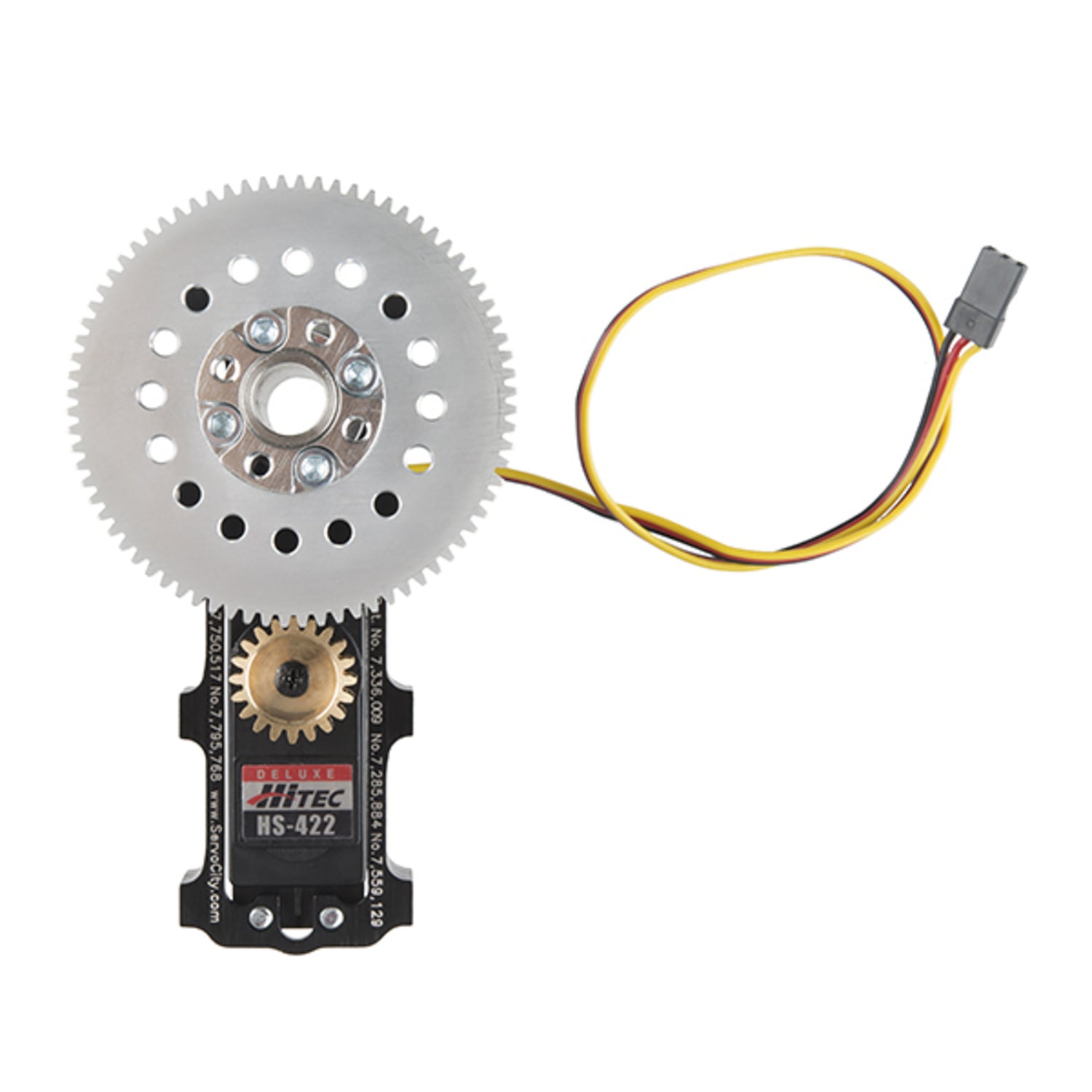

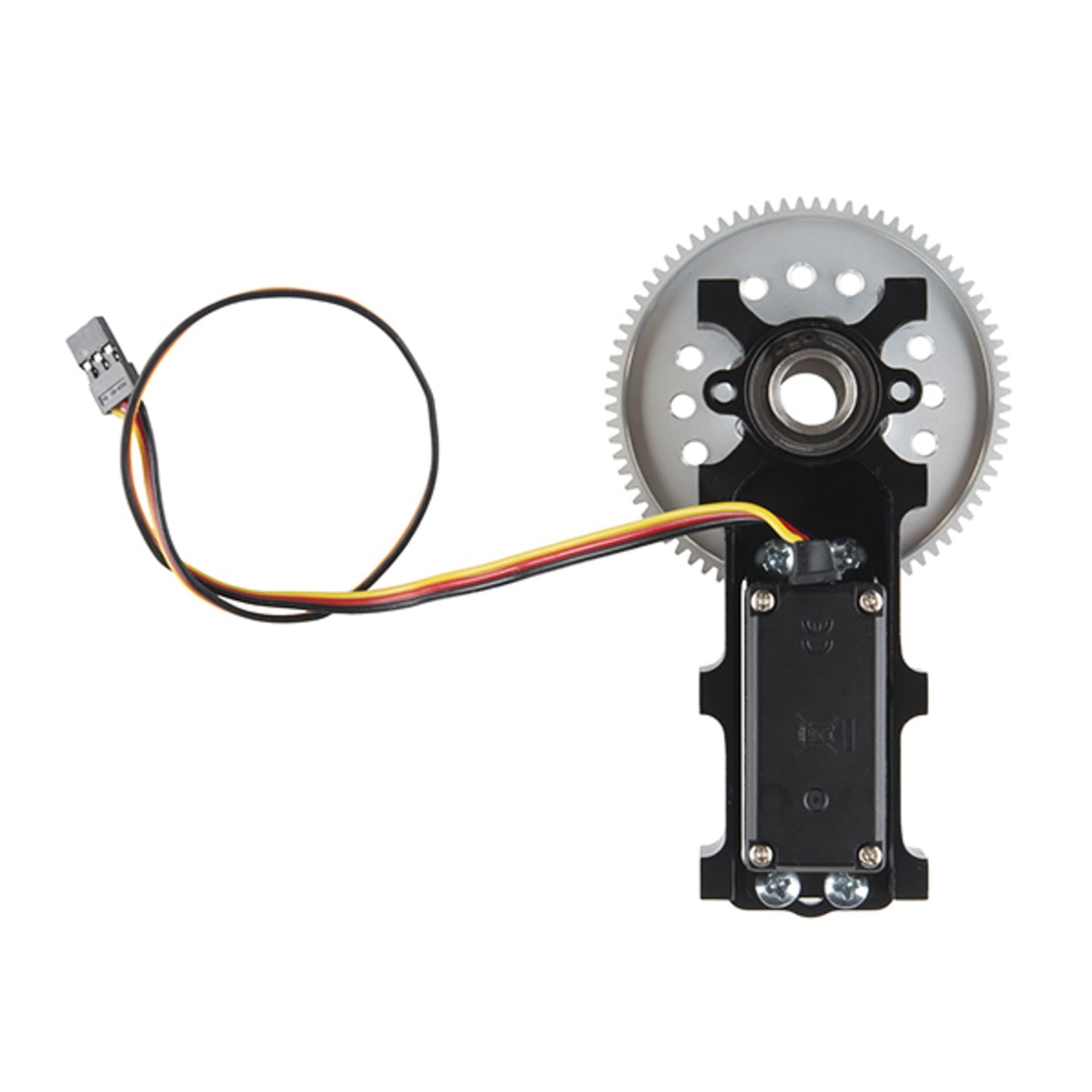

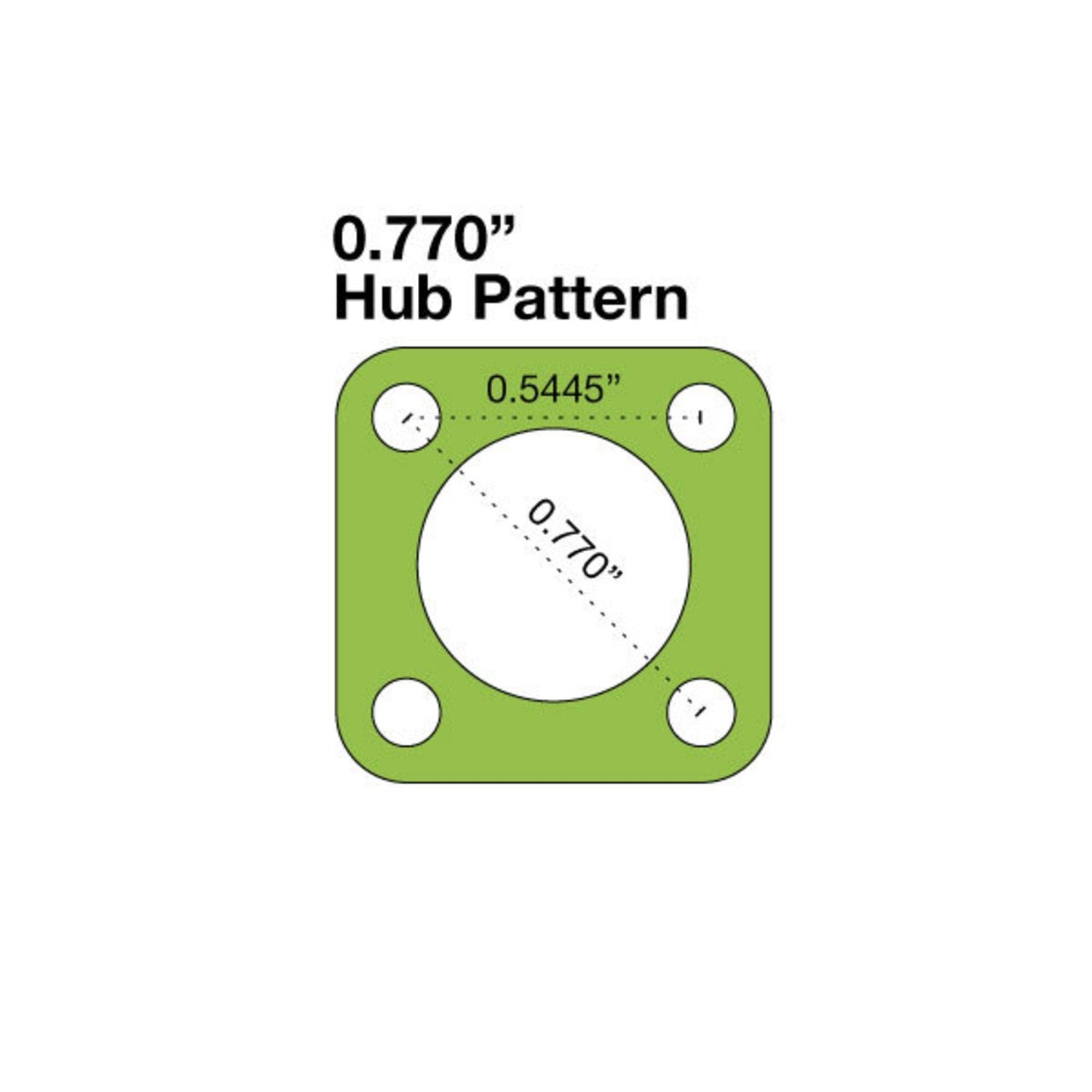

These continuous rotation channel gearbox kits with a 7:1 gear ratio feature threaded side mounts. You can easily attach a standard - sized servo to many Actobotics products like tubing and channel. It's a breeze to add a servo - powered gearbox to your custom pan & tilt setup, mechanical device, or robotic structure. The gearbox kit comes with a hardened 1/2” stainless - steel final shaft supported by dual ABEC - 5 precision ball bearings. It can handle up to 200 pounds of vertical and horizontal loads. The output shaft has a 0.382' bore, allowing you to pass wires through the center axis. Actobotics is a robotics building system using extruded aluminum channels, gears, precision shafts, and ball bearings. Thanks to two standardized hole patterns, most Actobotics components can be connected intuitively. This wide range of components makes building complex electromechanical prototypes or finished projects possible. Note: This gearbox kit doesn't include a servo. Check the related items for different Hitec servo options. Kit Includes: 1x Channel Mount Gear Box - Continuous Rotation, 1x Hub Mount Gear, 1x 7:1 Servo Gear, 1x Potentiometer Mounting Bracket, 1x 0.77' x 0.77' Servo Hub, 1x ½' Clamp Hub, 1x 6 - 32 x 3/8' Set Screw, 4x 6 - 32 x ½' Socket Head Screw, 4x 6 - 32 x ¼' Phillips Head Screw. Features: Unlimited rated rotation, 7:1 gear ratio, standard servo size, 0.77' hub pattern. Documents: Product Page (SPG400A - CM - CR7), Assembly Instructions.

Using this gearbox kit is easy. First, select a suitable Hitec servo as this kit doesn't come with one. Attach the servo to the channel mount gearbox using the provided screws. Then, connect the gearbox to your Actobotics products such as tubing or channel through the threaded side mounts. You can use the kit to build custom pan & tilt setups, mechanical devices, or robotic structures. When passing wires, make use of the 0.382' bore in the output shaft. Remember, this kit is only for Hitec servos. Avoid overloading the gearbox as the final shaft can support up to 200 pounds of vertical and horizontal loads. For maintenance, regularly check the screws to ensure they are tight. If the gears seem to be running rough, you can apply a small amount of suitable lubricant. Keep the kit in a dry place to prevent rusting of the stainless - steel shaft and other metal parts.